Modular scaffolding

One scaffold system,

limitless applications.

Ringlock.

One scaffold system,

limitless applications

Ringlock is a modular scaffolding system that caters to multipurpose and cost-effectiveness. Featuring the rosette and wedge-head locking mechanism, Ringlock revolves around a set of

core components that efficiently assemble into a robust steel structure to create a secure working area.

The streamlined assembling principle of Ringlock also make it stand for high efficiency. With a simple assembly process, all main components lock firmly in place with the help of a hammer. No need for bolts, screws, or mechanical tools.

From tanks, silos, spheres, rolling scaffolding, suspended scaffolding, heavy duty scaffolding applications to working platforms and towers for site access, its adaptability knows no bounds. With our extensive range of accessories, the options become limitless.

With few core components to setup most of the main scaffolding applications, Ringlock stands for high efficiency.

The wide range of accessories complements the simplicity of the rosette and wedge head connection, where a set of core components is assembled to create a stiff and safe access solution.

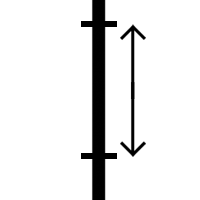

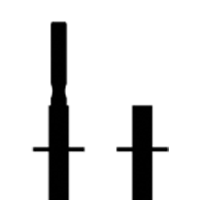

Standards with

welded rosettes.

Made of steel with galvanized finishing, the Ringlock Standards are a robust and durable scaffolding

component, as well as the main load bearing

component. With welded rosettes, Standards provide

a quick and secure assembly, support heavy loads,

and meets safety standards as they allow to attach

personal protective equipment. With multiple lengths available, the Standards are one of the core

components that ensure Ringlock its efficiency and adaptability.

Rosettes at each 50 cm

Welded directly onto the scaffolding pole, enhancing the connection possibilities..

8 holes per rosette

4 smaller holes at 90° intervals and 4 larger holes in between to allow for wider angles

With and without spigot

Spigots allow for easy and upright

stacking. Either crimped or bolted, for

regular or suspended applications,

respectively.

Casted wedge heads

With movable, but not detachable, wedges, to prevents loose components. Ensures a strong node connection.

Flexible dimensions

To adjust the scaffolding layout to the shape of the building.

Different options for different loads

Increase the load bearing capability by using truss ledgers or lattice girders.

Ledgers. A single

component for transoms and guardrails.

Ledgers are horizontal components that can serve as

structural elements, guardrails, or support for steel planks.

The integrated wedge head fits the rosette, with the wedge locking securely into the holes of the rosette. For wider scaffolding applications such as birdcage, cantilever, or suspended scaffolding, truss ledgers support planks and increase load-bearing capacity with their reinforced design.

Slide-in steel toeboards.

Quick to install, toeboards make up the 3-part edge protection required to help prevent dropped objects

from sliding off the scaffold.

The toeboards are installed behind the installed

wedge of a ledger, and can be installed longitudinally

and at right angles.

Slide-in fitting

Securely position toeboards behind the ledger wedges with a single motion.

Long lasting

Manufactured from galvanized steel with a painted finish, to be durable.

Compact stacking

The shape of the toeboards was designed for efficient stacking, facilitating storage and transportation.

Safety features for end-users

Rotating latch prevents accidental tilt, while

anti-slip surface enhances grip.

Sturdy and stable

The robust metal body ensures stability and confidence while walking.

Durable and impact resistant

Manufactured entirely from hot-dipped galvanized steel for extended durability

and strength.

Steel planks for a sturdy and safe work platform.

Ringlock planks are positioned atop the ledgers and secured safely with wind-latches. Stabilizers positioned at the edges guarantee a comfortable experience for workers, preventing tilting or shaking, even during heavy-duty tasks.

To enhance safety further, the perforated surface enables water to pass through, inhibiting the formation of ice and the accumulation of dirt. This design ensures that the walk-on surface remains non-slippery.

Get into the details

Learn about the main features of Ringlock's scaffolding steel planks

Diagonal bracing to ensure rigidity

The swiveling wedge heads at both ends lock onto the

rosette of the standards and form the vertical bracing

of the scaffold, to ensure its rigidity. Vertical bracings

come in differing lengths to suit any combination of

bay length and height.

For special applications, diagonals braces may also be

used to create suspended cantilevers on the

scaffolding.

Swivel wedge-heads

To enhance the the assembly of the bay braces on the standards.

Flexible dimensions

Each dimension of ledger and standard has its corresponding bay brace.

Cantilever solution

Larger cantilever work can be achieved with the use of diagonal braces.

When used in the industrial sector, Ringlock scaffolding enhances safety in hazardous environments, provides stable platforms for maintenance and repair work, and ensures efficient access to elevated and confined spaces.

A top choice for construction jobsites due to its exceptional flexibility and safety, the modular design of Ringlock allows for quick and easy assembly, adapting to complex structures and various heights. The secure locking mechanism ensures stability, providing a secure platform for workers. Additionally, the system's robust components and high load-bearing capacity enhance worker safety, making it suitable for a wide range of construction tasks.

Widely used across various industrial sectors, Ringlock is a heavy-duty scaffolding with benefits across any application.

From increasing safety with additional walkways and cantilevered expanded work areas to offering safety accessories for scaffolders during assembly, Ringlock scaffolding accelerates the speed of maintenance works providing access adapted to complex structures. This modular scaffolding system ensures cost efficiency by adjusting material usage according to load capacity needs and remains resourceful with its flexibility to fit every shape, always with the focus on the workers and end users.

Ringlock increases scaffolders' safety during assembly.

Ringlock scaffolding enables harness placement at specific connection points during assembly, such as rosettes and ledgers, significantly enhancing worker safety. Additionally, the use of advanced guardrails allows them to be placed on scaffolding levels ahead of those currently under construction, ensuring continuous fall protection before scaffolders arrive.

Ringlock enhances safety and efficiency in the oil and gas industry, streamlining operations to improve performance.

Ringlock scaffolding offers tailored solutions for the oil and gas sector, addressing the challenges of complex structures like refineries and offshore platforms. Its high-load capacity and quick assembly reduce downtime during plant maintenance. Advanced safety features, such as guardrails and secure connections, ensure worker safety in high-risk environments, while modular designs enhance access to confined spaces.

Designed for adaptability, Ringlock transforms manufacturing and industrial plants, optimizing workflows and productivity.

When it comes to industrial plants, Ringlock scaffolding streamlines operations by providing easy access to difficult areas. Its flexibility allows for efficient modification of scaffolding around machinery, minimizing disruptions. By reducing downtime, Ringlock scaffolding improves productivity in high-traffic areas while ensuring the safety of workers in confined, busy environments.

In the maritime sector, Ringlock provides critical support for shipbuilding, ensuring precision and reliability.

Ringlock scaffolding supports complex shipbuilding tasks through its modular design. Its flexibility allows it to adapt to narrow, sloped, or curved surfaces, such as hulls, making it ideal for repairs and upgrades in shipyards. The sturdy design handles heavy loads without compromising stability, providing safe and secure platforms at varying heights.

Ringlock guarantees safe access to towering structures in power generation and utilities, making maintenance and repairs straightforward.

For industries where maintenance of large structures is key, Ringlock scaffolding provides a tailored portfolio of accessories, such as our Boiler Founding System, required for working on furnaces, turbines, and cooling towers. Its adaptability allows for easy integration of essential accessories like platform brackets and stair towers which enhance both access and worker safety.

With exceptional durability and flexibility, Ringlock meets the rigorous demands of the mining industry.

In the mining sector, durability is essential to ensure the safety of workers. Ringlock scaffolding features heavy-duty components that withstand harsh environments, making it ideal for both underground and elevated access. Its modular design adapts to uneven terrains, metallic toe boards provide long-lasting protection, aluminum access decks ensure a lightweight, corrosion-resistant access solution. With Ringlock scaffolding, operators can benefit from safety and compliance with strict regulations, making it a trusted choice for mining operations.

In the pulp and paper sector, Ringlock delivers a reliable scaffolding solution that elevate productivity and safety in maintenance operations.

In the pulp and paper industry, maintaining large facilities can be a challenge. Ringlock scaffolding offers safe, quick assembly for plant repairs, pipe access, and machinery maintenance. Its modularity allows for flexible configuration around large machinery, reducing downtime and enhancing efficiency. The strong node connections ensure reliable support for workers performing high-risk tasks.

Custom and unconventional scaffolding solutions from Ringlock ensure that every project, no matter how unique, is met with tailored engineering designs and expert support, providing the right fit for any challenge.

"AT-PAC gear helped our business and our interactions with the teams, from design and consultation through to installation on site. We found that Ringlock minimises the labour quantities that we need on jobs, which also helps with transport."

Joshua Cope

RB Industrial Services

To fully unlock the system's potential, Ringlock offers a range of features and accessories designed to enhance safety, efficiency, and maximize versatility.

Color-codel label in all core components

A feature designed to simplify and enhance the scaffolding assembly. The smart identification labels streamline bay assembly, eliminating the need for constant measurements. Each color code indicates which components are compatible, ensuring a seamless fit every time. This intuitive system saves time and effort, allowing smarter and more efficiently scaffolding erection.

Lifting lugs for safe and efficient scaffold repositioning

Lifting lugs are essential for safe crane lifting of Ringlock scaffolding modules, including stair towers and rebar scaffolding. These accessories enable quick repositioning, allowing scaffolding to adapt to complex structures without disassembly. Perfect for overcoming site challenges, they ensure efficient access, maintaining worker safety while streamlining the movement of suspended scaffolding, working platforms, and shoring setups.

Steel staircase with disassemblable components

Designed to be maneuvered through manholes

and narrow industrial sites, this steel staircase can be fully disassembled into its individual components. The steps are separate pieces that fit into the stringers. Side protection is provided by diagonal bracings that also serve as railings, while the stair landings are made from scaffolding planks.

Mid-transoms for increased flexibility with obstacles

Mid-transoms allow for the creation of openings in the working platform to accommodate obstacles, such as struts supporting formwork panels. This enables scaffolding to remain close to the formwork, increasing worker safety without the need to redesign the scaffold’s overall structure. Mid-transoms can support one, two, or three steel decks and create openings between ledger to plank, plank to plank, and ledger to ledger connections.

Infill planks to ensure no gaps on the working platform

Uncovered gaps between planks and ledgers can lead to tripping hazards, tools or materials falling through, and instability on the working platform. Infill planks provide a seamless surface, reducing the risk of injury and enhancing the overall safety and efficiency of the scaffolding setup. By eliminating gaps, the scaffold also complies with safety regulations, creating a more secure environment for all workers on site.

Angle decks to adapt the scaffolding to circular shapes

AT-PAC’s angle decks are designed to adapt Ringlock scaffolding to circular shapes like tanks, silos, and chimneys. They create continuous, secure platforms around curved structures, eliminating gaps and improving safety. Fully compatible with our modular system, they allow crews to build efficient, clean scaffold assemblies without compromising on stability—ideal for industrial projects that demand both precision and speed.

Lattice girders to create larger spans of suspended scaffolding

Ideal to overcome large impediments on the façade, lattice girders double the span between two standards to create room for common obstacles on construction sites such as garage or truck entrances. These high load-bearing components can support steel decks, making them a safe choice for creating wider spans in cantilever or suspended scaffolding. Additionally, lattice girders can significantly reduce the amount of material needed in birdcage scaffolding assemblies for ceiling work.