THE IMPORTANCE OF 3D MODELING WHEN DETERMINING YOUR SCAFFOLDING SYSTEM NEEDS

July 12, 2019

Three-dimensional (3D) modeling has transformed a number of industries. It is used in medicine, filmmaking, interior design, and architecture to name a few. It is also used with great effect to help determine scaffolding system needs.

Using specialized software, 3D modeling develops a graphical model of a surface of an object. The model is often displayed as a two-dimensional image, but it can also be created in three dimensions using 3D printing.

Computer graphics technology first emerged in the 1960s, but it was not until the 1970s that 3D modeling software became commercially available. Today, the market for 3D content continues to thrive through marketplaces like Turbosquid and CGTrader.

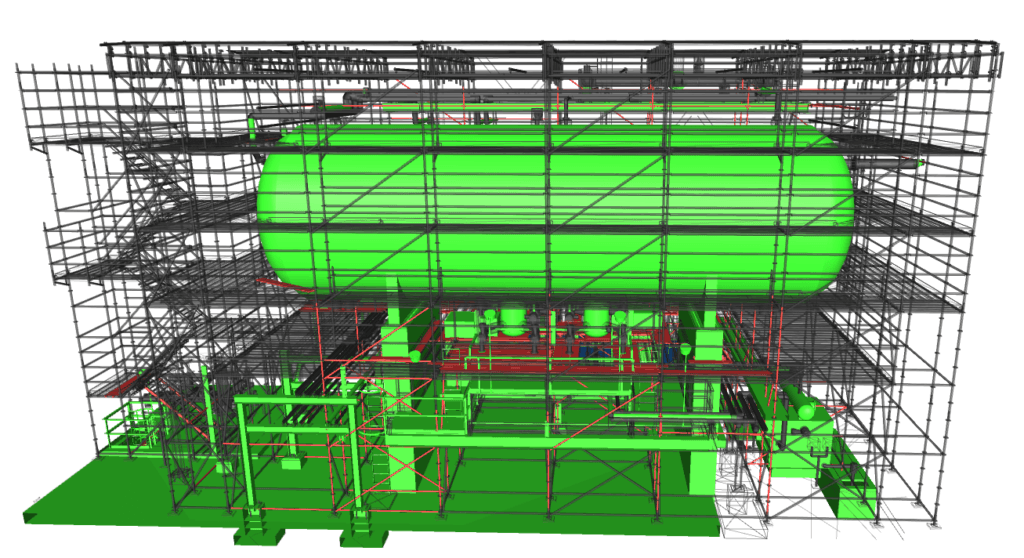

In the construction and industrial sectors, engineers use 3D modeling to help determine their scaffolding system

needs and often include 3D renderings in reports and proposals. Let’s take a closer look at how 3D modeling is used to determine scaffolding requirements.

Using 3D Modeling to Determine Materials and Estimate Costs

Many contractors and engineers use 3D modeling to help them navigate the scaffolding system selection process more efficiently. This technology helps:

- Create materials lists

- Create quotes and estimates

- Visualize scaffolding structures

- Save on engineer’s fees

Using 3D modeling ensures scaffolding structures are compliant before they are ever constructed. Additionally, the technology can be used to analyze existing structures to identify noncompliant areas and inefficiencies

Scaffolding design software

Application engineers use the most advanced industry design software to develop scaffold designs

and material lists, including:

- AutoCAD 2D & 3D

- Navisworks for building information modeling

- Solidworks for product design and animations

- Scaffold Designer for unique, customizable components, to build materials lists and calculate leg loads while building plans. It also integrates with AutoCAD

- Smart Scaffolder to import 2D CAD files and plans and create 3D project estimates and quotes. Smart Scaffolder also ensures your plans are in compliance with TG20:13 criteria

These technologies help create a realistic representation of your scaffold. The 3D-modeling process can be particularly advantageous when working on unique structures that require abnormal scaffolding solutions.

AT-PAC custom engineers scaffolding solutions

that meet the parameters of even the most unique projects. Contact us if you want to explore the creation of a scaffolding system that fits all of your projects needs, or call the regional office closest to you. We will discuss the challenges you face and find a solution that works.

You might also like

AT-PAC Blog

AT-PAC expands presence in Latin America — with Mexico established as key operational hub AT-PAC, one of the world’s leading scaffolding solution providers and part of umdasch Industrial Solutions, announces the launch of its new operation in Mexico. With this development, AT-PAC strengthens its industrial footprint in Latin America, offering immediate availability of AT-PAC Ringlock System Scaffolding, applied engineering support, and direct operational readiness for high-performance industrial projects. Mexico City, 08.01.2026. Well established across the USA, Canada, Europe, Australia, the UK and multiple LATAM regions, AT-PAC now advances into Mexico — a strategic market with growing industrial demand and large-scale operational potential. The expansion aims to support EPCs, asset owners and contractors with local inventory, engineering guidance and high-efficiency industrial access solutions. AT-PAC guides customers through the full lifecycle of an industrial scaffolding project — from engineering, documentation and planning, to material supply, field support and digital asset control. The core objective remains unchanged: safety, precision and performance in industrial environments. Direct value for the Mexican market According to Isaac Tovar, Commercial Director Mexico, the company’s arrival represents more than material access — it is a technical and operational support system designed to prevent downtime; "Every industrial challenge in Mexico becomes our mission. We respond with engineering, local availability, and specialized technical support to ensure continuity and efficiency in every project." With inventory positioned locally and a dedicated commercial and engineering team, Mexico now gains faster turnaround capabilities for high-demand industrial operations. Looking ahead For Rodrigo Arce, Regional Director LATAM, this is only the beginning of AT-PAC’s long-term vision in the region; "Mexico is a strategic point for Latin America. This operation strengthens capacity, accelerates response and establishes a new industrial scaffolding standard for the region." Alongside material availability, the Mexico hub will offer: ✔ Ringlock System Scaffolding for sales & rental ✔ Engineering, design & technical planning for industrial access ✔ On-site support and safe execution consulting ✔ Hi-Vis Scaffold Management Software for digital control and traceability ✔ Technical documentation, training and operational partnership

For nearly a decade, AT-PAC's Baton Rouge branch has been a cornerstone of our southern U.S. operations, proudly supporting projects across Louisiana, Missouri, Arkansas and Mississippi. Known for their dependable service and deep industry knowledge, the Baton Rouge team continues to strengthen AT-PAC's presence in the region - helping customers keep projects on track and on time. Under the leadership of Branch Manager Jeremy Smith, this experienced team has built lasting relationships through reliability, responsiveness, and a hands-on approach. Their recent move to a larger, upgraded facility marks an exciting new chapter - expanding their capacity to serve more customers, more quickly than ever before. Hear from Jeremy below about the team's new space, their commitment to customers, and how Baton Rouge continues to raise the standard across the South. Ready to reach out to the team? Contact them here .